Indoor Rowing Machine Maintenance: Complete Checklist

Taking care of your indoor rowing machine is crucial to ensure it lasts longer, performs efficiently, and remains safe to use. Neglecting maintenance can lead to costly repairs, reduced performance, or even safety risks. Here’s a quick look at what you need to do:

Key Maintenance Tasks:

- Daily Cleaning: Wipe down high-touch surfaces (handle, seat, rail, footrests) after every use to prevent sweat and dust buildup.

- Weekly Cleaning: Use soapy water to deep clean all surfaces and dry thoroughly.

- Lubrication: Apply 3-IN-ONE oil or 20-weight motor oil to the chain every 50 hours of use (or every 3 months for home use).

- Inspections: Monthly checks for loose screws, worn parts (seat, straps, rails), and chain stiffness.

- Yearly Deep Maintenance: Clean internal parts, recalibrate drag factor, and tighten all fasteners.

Quick Tips:

- Use microfiber cloths for screens and avoid harsh chemicals on metal or plastic parts.

- Store your machine in a dry, clean space to prevent rust.

- Replace worn parts like seat rollers or foot straps promptly to avoid further damage.

By dedicating a few minutes to regular upkeep, you’ll save time, money, and frustration while keeping your workouts smooth and effective.

Complete Guide to Row Machine Maintenance

Daily and Weekly Cleaning Tasks

Maintaining simple cleaning routines is key to keeping your machine in top shape and extending its lifespan. Sweat and dust can lead to corrosion and reduced performance if neglected. By incorporating daily wipe-downs and weekly deep cleaning, you can prevent grime buildup and ensure everything runs smoothly. Start by focusing on the surfaces you touch most often for quick, effective upkeep.

Cleaning High-Touch Surfaces

Areas like the seat, handle, rail, and footrests are high-contact zones that need daily attention. After each workout, use a soft, damp cloth to wipe these surfaces, paying special attention to grips and the seat. For the monorail where the seat slides, use soapy water or glass cleaner with a non-abrasive scouring pad to clear away dust, debris, and sweat effectively.

"Clean before and after every row, ski, or ride, making sure to clean grips, handlebars, and other common touch surfaces." – Concept2

Once a week, take cleaning a step further by mixing a small amount of dish soap with warm water. Wipe down all surfaces and dry them thoroughly with a towel to prevent moisture from lingering. Fitness expert Sydney Bueckert from Sunny Health & Fitness emphasizes:

"Completing regular cleaning and maintenance checks on your rowing machine will keep everything running smoothly, to ensure your workout is safe and effective." – Sydney Bueckert, Sunny Health & Fitness

Cleaning Electronic Components

Digital monitors and displays need extra care. Use a microfiber cloth to gently wipe screens and buttons, avoiding oversaturation to remove fingerprints and dust. Never spray cleaners directly onto these components or use abrasive products. Once a week, clear dust from vents and connection points using compressed air or a dry microfiber cloth. For stubborn spots, lightly dampen the cloth with a 70% alcohol solution (either isopropanol or ethanol) and clean carefully.

Additionally, check the battery compartments during your weekly routine. If the machine won’t be used for a while, remove the batteries and inspect for corrosion. These small steps can go a long way in preserving your machine’s performance.

Stopping Rust and Corrosion

Moisture is the enemy of metal components, so it’s essential to dry all metal surfaces immediately after workouts, especially areas prone to sweat accumulation. For regular cleaning, Simple Green All-Purpose Cleaner works well on steel, rubber, and vinyl parts. Avoid using harsh chemicals like concentrated alcohol, bleach, or ammonia, as they can damage the equipment.

Finally, always store your rowing machine in a clean, dry location to protect it from excess moisture and dust. These daily habits create a solid foundation for more in-depth maintenance down the line.

Lubrication and Moving Parts Care

Keeping your rowing machine’s moving parts properly lubricated is crucial for reducing friction and preventing premature wear. A well-lubricated chain ensures quiet, efficient operation, while neglected parts can lead to performance issues and a shorter lifespan for your equipment. The secret lies in using the right lubricants at the right intervals, depending on how frequently you use your machine.

Chain Lubrication Steps

Regular chain lubrication is a must. CRC White Lithium Grease is a reliable choice for rowing machine chains, offering long-lasting protection without attracting dust or debris. For home users, applying lubricant every three months usually works, while commercial facilities should aim for every 50 hours of use or weekly maintenance.

To lubricate your chain:

- Pull the handle all the way out to expose the entire chain.

- Using a rag, apply about 2 teaspoons of 3-IN-ONE oil to the chain.

- Pull 10-20 strokes to evenly distribute the lubricant.

- Allow the chain to retract fully into the system.

"A dry chain will not run as smoothly or as quietly as it should, and will wear out more quickly." – Will Spalding, Technical Support Specialist, Concept2

While lubricating, take a moment to inspect the chain for any stiff or frozen links that could cause irregular movement. If you notice jumps or resistance while pulling, these are early signs of potential issues. Lubrication might resolve the problem, but if not, it could mean the chain needs replacing.

After addressing the chain, check all moving joints and pivots. Ensure they have adequate grease, and tighten any loose screws you find. Also, inspect the flywheel for dust buildup and vacuum it if necessary.

Products to Avoid

Not all lubricants are suitable for rowing machines. For instance, WD-40 is not recommended for chain lubrication as it evaporates quickly and leaves behind a sticky residue. While it’s effective for cleaning and moisture displacement, it doesn’t provide the long-term lubrication needed for moving parts.

High-solvent bike chain oils can also cause issues. They may break down existing lubricants or damage rubber seals, so it’s best to stick to products specifically designed for exercise equipment or those recommended by the manufacturer.

The go-to lubricant for rowing machine chains is 20-weight oil, such as 20-weight motor oil, 3-IN-ONE oil, or mineral oil. These options provide consistent lubrication without the drawbacks of specialty sprays or cleaners.

Another excellent option is PlanetSafe‘s AiM Extreme Duty Lubricant, which has received a 4.6/5 star rating on Amazon from 272 customers. This lubricant uses nano-bonding technology to maintain slickness without drying out or leaving a sticky residue.

"AIM’s nano-bonding technology provides lasting slickness without residue, ensuring longer protection and reducing re-application." – PlanetSafe Lubricants

Investing in high-quality lubricants not only ensures smoother operation but also extends the life of your rowing machine’s components. PlanetSafe offers a variety of products tailored to meet different maintenance needs.

Inspection and Tightening Tasks

Keeping up with regular inspections is essential for spotting small issues before they turn into expensive repairs. A monthly check can make all the difference, as long as you know what to look for and have the right tools on hand.

Parts to Check Regularly

Once you’ve cleaned and lubricated your machine, it’s time to inspect key components for wear and tear. Monthly inspections are a great way to catch loose parts or signs of damage early. For example, in December 2021, HomeFitnessCode recommended a monthly inspection routine for rowing machines, allowing users to replace parts before excessive wear occurs.

Start with the chain and drive system. Check for stiff chain links that might create jerky or uneven strokes. If you notice resistance or irregular movement when pulling the handle, it could signal a chain issue that needs immediate attention. Make sure to inspect the chain-handle connection every 250 hours of use to confirm it’s secure.

Next, look at the seat and slide rail. Ensure the seat rollers move smoothly and check for cracks or excessive wear. The slide rail should also be clean and free of debris to prevent the seat from sticking or moving unevenly.

The foot straps and pedals take a lot of stress during workouts. Inspect the foot straps for fraying or cracking and confirm they stay securely routed through the buckle. Check the pedals to ensure they’re firmly attached, with no cracks around the mounting points.

Examine the flywheel housing for dust buildup. Use a vacuum to clean the area and inspect the shock cord every 250 hours of use. This helps keep the machine running smoothly. While you’re there, spin the flywheel to make sure it moves freely without wobbling or making strange noises.

Lastly, check all major connection points, including bolts, screws, and shock cords. Pay extra attention to areas where frame parts meet, as these spots are more likely to loosen over time.

Tools and Safety Tips

Once you’ve identified potential issues, having the right tools and following safety precautions will make maintenance easier. Most rowing machines come with basic tools, but adding a few extras can help you stay prepared.

Essential tools include an Allen wrench (often provided with the machine), a standard screwdriver set, and an adjustable wrench. Some manufacturers also include specialized tools for their equipment – keep these in a dedicated maintenance kit so they’re always easy to find.

For Concept2 machines, it’s especially important to check eight screws at the front of the machine: four on the legs and four under the flywheel. UCanRow2 highlighted this in November 2012, emphasizing how quick and simple this task can be.

"One of the most important things to check on a regular basis is the eight screws at the front of the machine – four on the legs and four under the flywheel… It’s an easy fix, just grab the allen wrench that came with your machine, tighten the screws, and voila, smooth water ahead yet again!" – UCanRow2

Safety is key during any maintenance. If your machine has electronic components, unplug it before starting. Make sure the equipment is on a stable, level surface to prevent movement while you work.

When tightening screws, do so gradually until they’re snug – over-tightening can cause damage. If a screw or bolt isn’t tightening properly, stop and check for issues like a stripped thread or cross-threading.

Pay attention to unusual sounds like hissing, clunking, or grinding, as these can signal mechanical problems. Keeping a log of your maintenance checks and noting any wear or issues can help you spot patterns and address problems early.

For more serious issues, like cracked frames, worn bearings, or electronic malfunctions, it’s best to contact the manufacturer or a professional repair service. Regular inspections and adjustments will keep your machine performing at its best, as discussed in previous sections.

Problem Solving and Long-Term Care

Routine upkeep is the key to avoiding problems and keeping your machine running smoothly. Tackling minor issues early and committing to a yearly deep maintenance routine can significantly extend the lifespan of your equipment.

Common Issues and Fixes

Most common problems are easy to address with a little attention. For instance, unusual noises often signal that something needs checking. If you notice squeaking during use, inspect the seat and rails for scuff marks or scratches. Roll the seat back and forth to pinpoint the source of the sound.

A creaking noise near the footplate usually indicates friction between the monorail and the front end of the machine. To resolve this, detach the monorail from the front section and apply a light coat of petroleum jelly to the aluminum hooks located at the front and rear-facing areas of the monorail.

When it comes to chain issues, a sticky or skipping chain might not always be solved by cleaning and lubrication. If the problem persists, inspect the sprocket for wear and reach out to the manufacturer for assistance.

As Balkan boy, a 1k Poster, wisely said:

"If it has moving parts, it needs lubrication".

For display and electronic problems, start with the basics. Check the battery levels or update the software. If the monitor isn’t working correctly, replacing the batteries is often the simplest first step before diving into more complex troubleshooting.

Here’s a quick guide for common problems and their solutions:

| Problem | Cause | Solution |

|---|---|---|

| Black residue on monorail | Dirt, sweat, lubricant, and plastic buildup | Wipe down with soap, water, or glass cleaner using a cloth or non-abrasive pad |

| Bumpy seat or clicking sounds | Dirt buildup or worn seat rollers | Clean the rollers and monorail; replace rollers if the issue persists |

| Chain skipping or running roughly | Stiff chain links | Clean and lubricate the chain thoroughly |

| Scraping noise near the front beam | Worn or misaligned shock cord/chain | Check the routing; contact the manufacturer for replacement parts if needed |

| Creaking from footplate area | Friction between monorail and front end | Apply a thick lubricant to the aluminum hooks on the monorail |

Uneven resistance is often caused by user settings rather than mechanical issues. For example, setting the resistance too high can make your workout unnecessarily difficult. If you’re dealing with this, review your rowing technique. Recording yourself or using mirrors can help identify and correct any form issues.

To avoid recurring problems, incorporate annual deep maintenance into your routine.

Yearly Maintenance Tasks

Deep maintenance once a year can prevent major issues and keep your machine in peak condition. Set aside 15 to 30 minutes for these tasks, which go beyond the usual cleaning.

Start with electronic upkeep, like updating monitor batteries and software. Software updates are often overlooked but can enhance performance and even add new features.

Internal cleaning requires removing the flywheel cover to clear out dust and debris. Pay close attention to the shock cord routing to ensure it hasn’t shifted or suffered wear from rubbing against other parts.

The monorail also needs detailed care. Clean it thoroughly, check for alignment issues, and inspect the seat rollers for flat spots or cracks that could lead to future problems.

Inspect the handle and foot stretchers, focusing on connection points and moving parts. Look for wear on the handle grip and weak spots in the foot straps from repeated use.

Drag factor calibration is another important step. Dust and wear can affect the drag factor over time, so recalibrate it according to your machine’s specifications for consistent performance.

Finally, tighten all fasteners beyond your regular checks. Open panels if possible to access internal bolts and screws that may have loosened due to vibration. Pay special attention to the frame and mounting hardware.

Keep a record of your yearly maintenance. Take photos, make notes about wear patterns, and save receipts for replacement parts or professional services. This documentation can help you spot recurring issues and may be useful for warranty claims down the road.

Products and Resources for Maintenance

Keeping your rowing machine in top shape requires the right products and services. By using high-quality cleaning solutions, effective lubricants, and having access to replacement parts, you can significantly extend the life of your equipment. Here’s a breakdown of recommended products and resources to simplify your maintenance routine.

Recommended Maintenance Products

When it comes to cleaning, Concept2 suggests using either a diluted bleach solution or alcohol with at least 70% isopropanol or ethanol. To prepare a bleach solution, mix 1/3 cup of 6% bleach with one gallon of water. Apply it to surfaces, let it sit for at least one minute, and then wipe it down.

For chain lubrication, here are some great options:

- 3-IN-ONE Multi-Purpose Oil: A 3-ounce bottle costs $4.00 directly from Concept2.

- TreadLife Fitness Concept 2 Rowing Machine Chain Oil: Available on Amazon for $14.95.

- UniSport Concept 2 Rowing Machine Chain Oil: An 8-ounce bottle priced at $13.99 at Walmart.

If you own a water rowing machine, water purification tablets are essential to keep the tank clean and free from grime. A 4-tablet pack is priced at $14.95. One satisfied Amazon customer, Vanessa, shared her experience:

"I love how easy they are to use, just drop in my rower and done!"

For those looking for eco-friendly options, consider PlanetSafe Exercise Equipment Lubricant for $29.99 on Amazon or a Versatile Non-Toxic Lubricant suitable for various equipment, available in a 16-ounce size for $94.97 on eBay.

To maintain your rowing machine effectively:

- Use water purification tablets every 3–6 months.

- Lubricate the chain after every 50 hours of use.

- If the water tank gets dirty, flush it with rubbing alcohol before refilling.

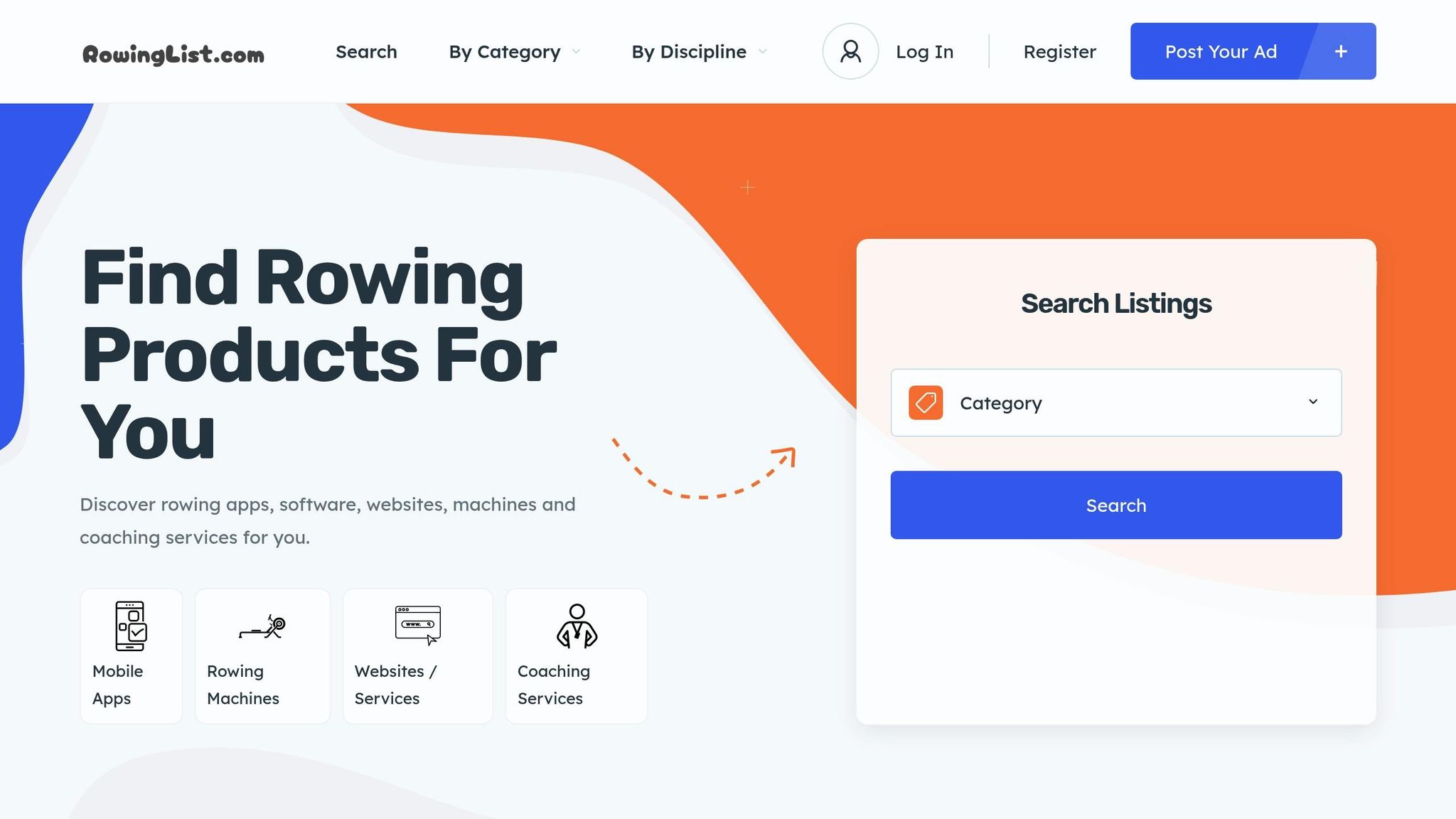

Using RowingList.com for Parts and Services

RowingList.com is a convenient platform that organizes rowing-related products and services into easy-to-navigate categories. Whether you’re looking for maintenance tools, replacement parts, or professional services, this site has you covered. You can even filter options based on your rowing preferences – indoor, on-water, or virtual.

For professional support, several service providers stand out:

- Gym Tech Service: Specializes in indoor rower repair and maintenance for brands like Concept2 and WaterRower. They offer services like preventative maintenance, equipment repair, delivery, and more. Contact them at 866-GYM-TECH.

- Huff-n-Puff Fitness Repair: Operating in Illinois and Wisconsin, they handle cleaning, calibration, lubrication, diagnostics, and parts replacement. Contact them at 708-294-2945 for Chicagoland or 414-246-8991 for Milwaukee/Madison areas.

- CrossFixIt Equipment Services: Provides routine maintenance, safety inspections, troubleshooting, repairs, and parts sales for brands like Concept2 and True Fitness.

RowingList.com also offers free basic listings for unlimited submissions, while featured listings start at $30 for 30 days, giving businesses enhanced visibility. The platform’s product comparison tool allows you to evaluate different maintenance products and services side by side. Plus, its integration with platforms like Concept2 Logbook and Strava ensures seamless performance tracking and data management.

For genuine replacement parts and additional advice, visit the Concept2 website, or explore the directory listings on RowingList.com.

Conclusion

Taking good care of your rowing machine not only extends its lifespan but also keeps it performing at its best. The key lies in three simple steps: regular cleaning, proper lubrication, and routine inspections.

Take Concept2 rowers, for instance – machines that are well-maintained according to the manufacturer’s guidelines can stay in excellent condition for over a decade. On the other hand, neglecting maintenance can lead to costly repairs within just a few years, sometimes running into hundreds of dollars. Spending just a few minutes on upkeep after each workout can save you time, money, and frustration down the road.

Daily cleaning is essential to prevent sweat and dust from accumulating, which can cause rust or mechanical problems. Weekly checks for loose bolts and consistent lubrication help ensure all parts are running smoothly. These small, consistent efforts go a long way in preserving your machine’s functionality.

Maintenance also plays a big role in safety and performance. A well-cared-for rowing machine provides steady resistance and stability, reducing the chances of accidents during use. Whether you’re a weekend rower or someone training daily, keeping your machine in top shape ensures a reliable workout every time. Stick to manufacturer-recommended cleaning products like mild soap, water, or glass cleaner, and steer clear of harsh chemicals that could damage your equipment. If you notice any worn parts, replace them promptly with authentic components to maintain both safety and performance.

FAQs

How often should I perform thorough maintenance on my indoor rowing machine, and what steps are involved?

Maintaining your indoor rowing machine properly can keep it running smoothly and extend its lifespan. A comprehensive maintenance session is recommended every 1–2 years, or after logging about 5,000 to 10,000 hours of use, depending on how frequently and intensely you use the machine. Here’s what that usually involves:

- Deep cleaning to clear out dust, dirt, and grime that can build up over time.

- Lubricating key components like the chain or seat rollers to ensure smooth movement.

- Inspecting for signs of wear, such as stretched chains, damaged belts, or loose screws.

- Replacing any worn-out parts to keep the machine functioning at its best.

- Checking the resistance mechanism to confirm it’s operating without issues.

For regular upkeep, make it a habit to perform monthly checks. This includes cleaning the machine, looking for visible damage, and tightening any loose parts. Always refer to your manufacturer’s manual for specific maintenance guidelines tailored to your model.

What are the best cleaning and lubrication products to maintain my rowing machine?

To keep your rowing machine running smoothly and in great shape, you can use household disinfectant sprays, a mild bleach solution (mix 1/3 cup of bleach with a gallon of water), or specialized products like the WaterRower Care Set or Concept2 cleaning kits. These options are designed to clean effectively, protect the components, and even handle lubrication when needed.

Make sure to always check and follow the manufacturer’s cleaning and maintenance guidelines. By sticking to these recommendations, you’ll not only avoid potential damage but also extend the lifespan of your rowing machine, ensuring it delivers a consistent and dependable workout experience.

How can I tell if my rowing machine needs maintenance or a part replaced?

If your rowing machine is producing persistent squeaking or grinding sounds, has a stiff or wobbly seat, or you notice unusual vibrations, it’s likely time for some maintenance. Other red flags include problems with the display panel, visible wear or damage to parts like the chain, belts, or pulleys, or difficulty achieving a smooth rowing motion.

Taking the time to regularly check your machine for these issues can save you from bigger headaches down the line. Fixing problems early not only helps your equipment last longer but also ensures your workouts remain safe and enjoyable.